Top Advantages of Using Film-Faced Shuttering Plywood — Yafa Contractor’s Guide

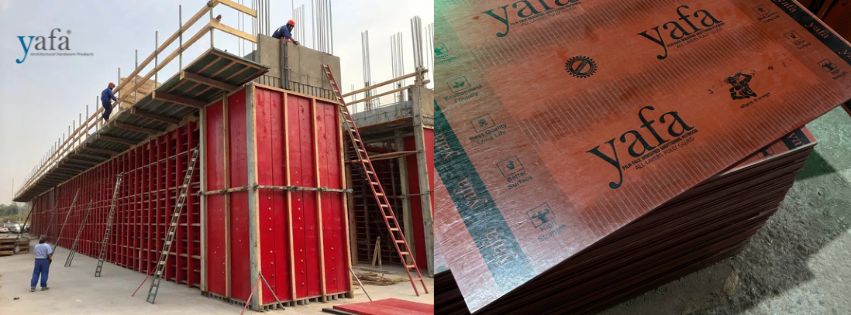

When contractors want high-quality concrete formwork, Yafa film-faced shuttering plywood delivers a reliable and cost-effective solution. Yafa engineers its shuttering plywood for maximum strength, excellent water resistance, and smooth concrete finishes — making it ideal for everything from residential slabs to heavy commercial structures. In this article, we clearly explain the advantages of film-faced shuttering plywood and show how choosing the best film-faced plywood in India helps builders save time, reduce costs, and minimise rework on construction sites.

What is Film-Faced Shuttering Plywood?

Film-faced shuttering plywood is plywood bonded with multiple veneers and coated on both sides with a tough phenolic film. This film creates a non-porous layer that resists water, concrete chemicals, and abrasion. Yafa uses carefully graded hardwood veneers and an industrial-grade phenolic film to deliver consistent thickness, dimensional stability, and a smooth, release-friendly surface.

Why Choose Yafa Film-Faced Plywood for Formwork?

Yafa manufactures high-performance film-faced shuttering plywood designed specifically for concrete formwork applications. It withstands the heavy pressure of wet concrete and delivers a consistently smooth surface finish that reduces plastering and labour time. Below are the main advantages of film-faced shuttering plywood that make Yafa a trusted choice for contractors and developers.

1. Exceptional Load-Bearing Strength

Yafa shuttering plywood uses high-density hardwood cores and a superior bonding process, giving it excellent bending strength and shear resistance. This means the formwork remains stable during pouring and curing — a must for multi-storey projects and heavy structural elements.

2. True Waterproof Performance

The phenolic film on Yafa plywood creates a waterproof barrier that prevents swelling and delamination when exposed to wet concrete and site weather. For contractors looking for the best waterproof shuttering plywood for concrete, this reduces material waste and extends usable life on-site.

3. Smooth, Repeatable Concrete Finish

A film-faced surface releases concrete cleanly and leaves a smooth, low-porosity finish. That reduces the need for plaster or heavy surface preparation. For builders who demand a high-quality facade or exposed concrete texture, Yafa plywood delivers consistent results across multiple pours.

4. High Reusability — Greater Project Economies

One of the clearest cost advantages is reusability. Properly handled Yafa film-faced shuttering plywood sheets can be reused 10–15 times (often more under careful use). This makes Yafa an economical choice for contractors who run repeated formwork cycles on projects in Punjab, Haryana, Himachal Pradesh, and Jammu & Kashmir.

5. Resistant to Termites, Fungus & Site Chemicals

The film coating protects the wood from biological attack and site chemicals. In humid regions or monsoon seasons, the extra protection prevents damage and reduces long-term replacement costs.

6. Lightweight Handling & Faster Installation

Yafa sheets are designed to be strong yet manageable. Lighter panels mean faster framing, simpler handling, and safer on-site operations. Faster cycles directly translate to shorter schedule times and lower labor bills.

7. Dimensional Stability in Harsh Conditions

Good formwork must not warp. Yafa plywood maintains its shape under heat and humidity, preventing gaps, blowouts, and misalignment during concrete placement. This stability helps keep projects on schedule and avoids rework.

8. Versatile for Multiple Construction Applications

Yafa film-faced plywood is suitable for:

- Slab formwork and soffits

- Columns and beam formwork

- Falsework and panel systems

- Bridge decks and precast moulds

Practical Benefits for Contractors and Developers

Using Yafa film-faced shuttering plywood improves real-world site outcomes:

- Reduced finishing costs: smoother concrete means less plaster and fewer finishing hours.

- Lower lifecycle cost: reusable sheets reduce material procurement and disposal frequency.

- Consistent quality control: uniform panels reduce variability between pours and reduce defects.

- Faster cycle times: easy handling and quick release speeds up formwork turnover.

Tip: For best results, pair Yafa film-faced shuttering plywood with correct formwork oils and recommended handling practices. Proper cleaning and storage between uses will extend sheet life and maintain finish quality.

Buying Guide — What to Look for When Purchasing Film-Faced Plywood

When sourcing shuttering plywood, check for:

- Quality of veneers: uniform veneers with tight bonding reduce delamination.

- Core bonding strength: phenolic resin-bonded cores resist shear and bending.

- Film thickness & adhesion: thicker, well-adhered film surfaces last longer and release better.

- Certifications & test data: inquire about bending tests, water soak tests, and glue grade.

- Local availability: choose suppliers who deliver reliably to project sites in Punjab, Haryana, Himachal Pradesh, and Jammu & Kashmir.

Storage & Handling Best Practices

To maximize sheet life:

- Store under cover and off the ground to avoid moisture pickup.

- Clean concrete residues immediately after stripping.

- Use proper lifting equipment and avoid dragging sheets over rough surfaces.

- Inspect edges and film integrity before each reuse; repair minor damage promptly.

Benefits of Film-Faced Shuttering Plywood in Construction Projects – FAQs

1. What is film-faced shuttering plywood?

Film-faced shuttering plywood features a high-strength core and a waterproof film coating that protects it from moisture, weather, and chemicals during concrete construction.

2. Why is it used for formwork?

It is ideal for formwork because it can withstand the heavy pressure of wet concrete and ensures a smooth surface finish after the concrete sets.

3. How many times can film-faced plywood be reused?

High-quality film-faced shuttering plywood delivers better cost efficiency over time because you can reuse it multiple times with proper handling, storage, and a reliable brand quality.

4. Is it waterproof and durable?

Yes! The waterproof film and strong bonding ensure durability in humid and wet construction environments.

5. Does it improve the finish of concrete?

Absolutely. It produces smooth, clean concrete surfaces, reducing finishing time and labour costs.

6. Can it be used in all weather conditions?

Yes, it is designed to perform well in extreme weather, ensuring stability and safety on site.

7. Is it cost-effective for construction companies?

Because of its long reuse cycle and excellent performance, contractors save significantly on project costs.

8. How many times can Yafa film-faced shuttering plywood be reused?

With correct handling and maintenance, you can typically reuse the sheets 10–15 times or more depending on site conditions and care.

9. Is film-faced plywood better than steel formwork?

Both have advantages. Film-faced plywood offers faster setup and a high-quality finish at lower upfront cost; steel is durable for extremely high-cycle or specialty forms. Many contractors use a hybrid approach.

Conclusion — Why Yafa Film-Faced Shuttering Plywood Is a Smart Investment

For contractors and developers who prioritise quality, speed, and lifecycle economics, Yafa film-faced shuttering plywood is a practical solution. It combines waterproof performance, structural strength, and a smooth concrete finish — all while being lightweight and reusable. Whether you’re working on apartments in Chandigarh, a bridge project in Jammu, or infrastructure in Himachal Pradesh, Yafa plywood helps you deliver consistent, cost-efficient results.

Ready to upgrade your formwork?

Yafa is a leading manufacturer of high-quality film-faced shuttering plywood, renowned for its durability, superior finish, and reliable performance in construction projects. With a commitment to excellence and innovation, Yafa offers a complete line of plywood products that meet the highest industry standards, ensuring strength and longevity on every site. Contact Yafa for product specifications, local distributors, and bulk pricing information.

Leave a Reply