Shuttering Plywood: The Complete Buyer’s Guide (Types, Thickness, Reuse & Care)

The quickest way to achieve uniform concrete surfaces, clean edges, and straight lines is to do the formwork (shuttering) correctly. This helps prevent time-consuming rework. To make sure you choose the right shuttering plywood for your needs, it’s important to take into account a number of important factors. Yafa offers a thorough buyer’s guide in this blog to help you make an informed choice. The various kinds of shuttering plywood, how to determine the right thickness, strategies to increase reuse cycles, and a purchasing checklist to carry to the yard are all covered in this guide.

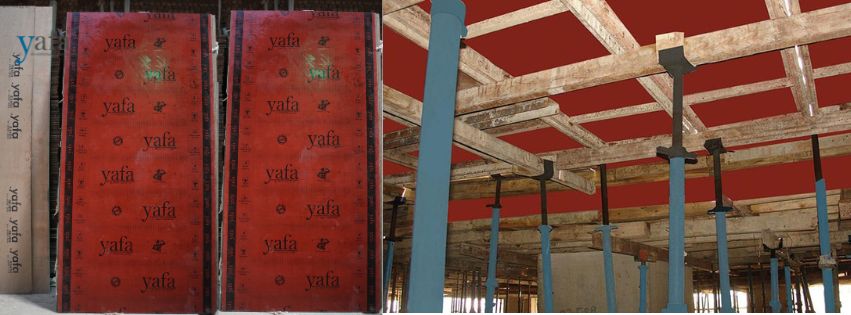

What Is Shuttering (Formwork) Plywood?

Shuttering plywood is engineered to build temporary molds that hold fresh concrete until it sets. Unlike interior plywood, it must tolerate high hydrostatic pressures, moisture, and repeated handling. Good shuttering boards maintain their shape, resist edge swelling, and release cleanly to leave a smooth cast surface.

Pro tip: Fewer joints and stiffer faces reduce honeycombing and patchwork on finished concrete.

Why the Right Shuttering Plywood Matters

- Smoother concrete: Film-faced sheets reduce bugholes and waviness.

- Faster cycles: Rigid panels + correct support spacing speed up pours.

- Cost control: Durable boards with higher reuse cut overall formwork cost.

- Safety & accuracy: Stable shuttering holds alignment for beams, columns, and slabs.

Types of Shuttering Plywood

1) Film-Faced (Phenolic Film) Plywood

- Phenolic film on both faces for water resistance and smooth finishes.

- Favored for repeat use and architectural concrete.

- Ideal for slabs, columns, beams, cores, and bridge decks.

- Often heavier; plan handling and safe lifting on site.

2) BWP / Marine-Attribute Plywood

- Made with boiling waterproof (BWP) bonding to resist delamination in wet conditions.

- Reliable in exposed pours, water-retaining structures, and monsoon-prone sites.

- Great pick when strength + moisture protection are both critical.

3) MR (Moisture-Resistant) Grade Plywood

- Budget-friendly option for low-risk, short-term or indoor formwork.

- Not fully waterproof—avoid direct rain exposure and prolonged wet use.

4) Hardwood Core Shuttering Plywood

- Dense, strong core for better load-bearing and reduced warping.

- Suited to heavy pours, wider spans, and sites requiring high rigidity.

5) Softwood Core Shuttering Plywood

- Lighter, easier to cut and handle; useful for residential slabs and short cycles.

- Expect fewer reuses; support more frequently to prevent deflection.

6) Fire-Retardant Variants

- Treated to improve resistance to flame spread when code or site policy requires it.

- Use where safety protocols demand additional protection.

Choosing Thickness, Size & Support Spacing

- Common thickness: 18 mm is widely used for slabs and general work.

- Go thicker for wider spans, heavier pours, or when support spacing can’t be tightened.

- Sheet sizes: 8×4 ft is common; fewer joints = better finish and faster work.

- Support spacing: Tighter centers minimize deflection and surface waviness.

- Edge sealing: Ask for factory edge-sealed panels to resist moisture ingress.

Grades, Glue Lines & Standards

- Prefer high-density film faces and calibrated cores for uniform rigidity.

- BWP bonding (phenol-formaldehyde) improves boil and weather resistance.

- Check for compliance with IS 4990 (formwork plywood) and, for marine attributes, IS 710.

- Inspect core gaps, face veneer quality, and press uniformity before buying.

Maximizing Reuse Cycles

- Use a compatible release agent (not diesel) to protect faces and speed de-shuttering.

- Pre-drill nail/screw points and avoid over-driving fasteners.

- Clean immediately after strike; avoid wire-brushing that scars the film.

- Reseal cut edges and damaged corners with sealant or edge paint.

- Store panels flat on dunnage, off the ground, away from direct rain and sun.

Smart Buying Checklist

- Surface: Uniform film with no bubbles, blisters, or resin starve marks.

- Core: Minimal core gaps; consistent ply count; tight bonding.

- Flatness: Check against a straight edge; reject warped or twisted sheets.

- Edges: Properly sealed; no voids or delamination signs.

- Stamping: Grade, thickness, and standard markings (e.g., IS 4990, IS 710 where relevant).

- Documentation: Ask for test reports or mill QC where available.

Common Mistakes

- Using MR-grade outdoors: Upgrade to BWP or film-faced for wet conditions.

- Wide support spacing: Tighten centers to avoid deflection and ripples.

- Wrong release agent: Use form-release oils designed for phenolic films.

- Rough cleaning: Use plastic scrapers; avoid metal scraping that tears film.

Quick Recommendations by Use-Case

- Architectural finish / repeat use: Film-faced, calibrated panels with BWP glue.

- Wet or exposed pours: BWP/marine-attribute plywood; reseal edges after cuts.

- Residential slabs (budget): Quality softwood or MR only for indoor, dry work; otherwise step up to BWP.

- Heavy infrastructure: Hardwood core or premium film-faced with tighter support spacing.

FAQs on Shuttering Plywood

Which plywood gives the smoothest concrete?

High-quality film-faced sheets typically deliver the smoothest finish with fewer blowholes.

Is 18 mm always enough?

It’s common for slabs and general pours, but span, load, and support spacing dictate thickness. When in doubt, go thicker and tighten centers.

How do I stop edges from swelling?

Use edge sealants, avoid standing water, and patch nicks immediately after each cycle.

How many reuses can I expect?

With careful handling, film-faced or BWP-bonded boards can be reused multiple times. Reuse depends on release agents, storage, and site discipline.

Conclusion

For crisp, repeatable results, choose film-faced or BWP-bonded shuttering plywood, keep support spacing tight, and follow a strict care routine. That combination consistently delivers smooth finishes, fewer defects, and better economics across multiple pours.

Need Help Picking the Right Sheets?

It’s crucial to choose the right shuttering plywood for your needs. For all of your plywood needs, Yafa is one of the most reliable and superior plywood manufacturers and suppliers. Yafa offers reasonably priced plywood that is suitable for a variety of uses. Our staff will recommend the best type, thickness, and spacing for your next pour based on your site’s characteristics, span, and pour depth. Contact us for project-specific recommendations.

Leave a Reply